什么類型的電纜橋架可以適應(yīng)潮濕惡劣的環(huán)境?

在潮濕、多水汽的惡劣環(huán)境中,電纜橋架的抗腐蝕、防滲漏能力直接影響電纜的運(yùn)行。普通材質(zhì)的橋架易受水汽侵蝕,導(dǎo)致結(jié)構(gòu)損壞或線路故障,因此需選擇專門針對潮濕環(huán)境設(shè)計的類型。這類橋架通過材質(zhì)改良和結(jié)構(gòu)優(yōu)化,能有效抵御水汽、鹽分等侵蝕,保障電纜長期穩(wěn)定運(yùn)行。

In harsh environments with high humidity and moisture, the corrosion resistance and leakage resistance of cable trays directly affect the safe operation of cables. Ordinary material cable trays are susceptible to water vapor erosion, leading to structural damage or line failures. Therefore, it is necessary to choose a type specifically designed for humid environments. This type of cable tray can effectively resist erosion such as water vapor and salt through material improvement and structural optimization, ensuring long-term stable operation of cables.

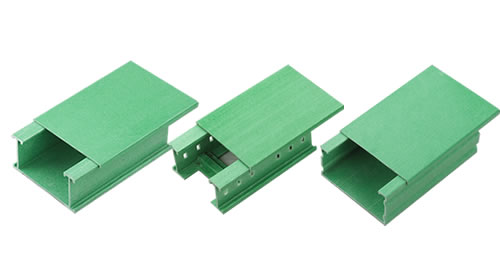

玻璃鋼電纜橋架是潮濕環(huán)境中的理想選擇。它以玻璃纖維為增強(qiáng)材料,以樹脂為基體經(jīng)復(fù)合成型,整體具有優(yōu)異的耐腐蝕性,不生銹、不老化,能抵御雨水、霧氣、工業(yè)蒸汽等多種水汽侵蝕。即使在沿海地區(qū)的高鹽霧環(huán)境或化工廠的潮濕腐蝕性氣體中,也能保持結(jié)構(gòu)穩(wěn)定,使用壽命可達(dá) 20 年以上。玻璃鋼材質(zhì)本身不導(dǎo)電,還能避免潮濕環(huán)境下的電化學(xué)腐蝕,同時其表面光滑,不易附著灰塵和水汽,減少了因污垢堆積導(dǎo)致的腐蝕隱患。此外,玻璃鋼橋架重量輕,安裝時無需重型設(shè)備輔助,適合潮濕環(huán)境下的復(fù)雜場地施工。

Fiberglass cable trays are an ideal choice for humid environments. It is reinforced with glass fiber and formed by composite molding with resin as the matrix. It has excellent corrosion resistance as a whole, does not rust or age, and can resist various water vapor erosion such as rainwater, mist, and industrial steam. Even in high salt spray environments in coastal areas or humid corrosive gases in chemical plants, it can maintain structural stability and have a service life of over 20 years. Fiberglass material itself is non-conductive and can prevent electrochemical corrosion in humid environments. At the same time, its surface is smooth and not easily adhered to dust and water vapor, reducing corrosion hazards caused by dirt accumulation. In addition, fiberglass bridge frames are lightweight and do not require heavy equipment assistance during installation, making them suitable for complex construction sites in humid environments.

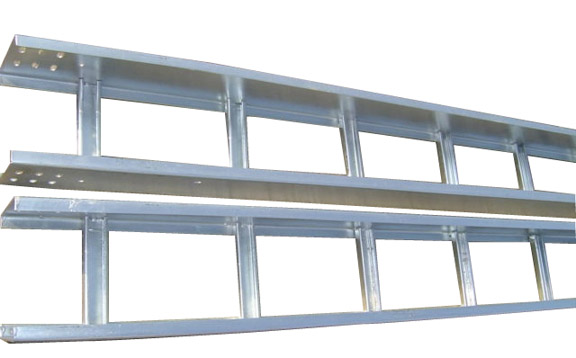

熱浸鋅電纜橋架通過表面處理增強(qiáng)了抗潮能力。它以鋼材為基材,經(jīng)高溫將鋅液浸鍍在表面,形成一層均勻致密的鋅層,鋅層能與水汽發(fā)生反應(yīng)生成致密的氧化鋅薄膜,阻止水汽進(jìn)一步滲透到鋼材內(nèi)部,起到犧牲陽極保護(hù)的作用。這種橋架能適應(yīng)多雨、潮濕的戶外環(huán)境,如露天變電站、污水處理廠等,即使鋅層局部受損,周圍的鋅也會繼續(xù)提供保護(hù),延緩基材腐蝕。熱浸鋅處理后的橋架結(jié)構(gòu)強(qiáng)度高,能承受較重的電纜重量,適合潮濕環(huán)境中需要承載大量電纜的場景,但其重量較大,安裝時需確保固定牢固。

The hot-dip galvanized cable tray has enhanced its moisture resistance through surface treatment. It is made of steel as the substrate, and zinc solution is immersed on the surface at high temperature to form a uniform and dense zinc layer. The zinc layer can react with water vapor to form a dense zinc oxide film, which prevents water vapor from further penetrating into the interior of the steel and serves as sacrificial anode protection. This type of bridge can adapt to rainy and humid outdoor environments, such as outdoor substations, sewage treatment plants, etc. Even if the zinc layer is partially damaged, the surrounding zinc will continue to provide protection and delay substrate corrosion. The bridge structure treated with hot-dip galvanizing has high strength and can withstand heavy cable weight, making it suitable for scenarios where a large number of cables need to be carried in humid environments. However, due to its heavy weight, it is necessary to ensure that it is firmly fixed during installation.

鋁合金電纜橋架在潮濕環(huán)境中表現(xiàn)穩(wěn)定。鋁合金本身具有一定的耐腐蝕性,其表面會自然形成一層氧化膜,這層氧化膜能阻止水汽和氧氣進(jìn)一步侵蝕內(nèi)部材質(zhì),在潮濕的室內(nèi)外環(huán)境中都能保持良好狀態(tài)。經(jīng)過陽極氧化處理的鋁合金橋架,表面氧化膜厚度增加,抗腐蝕能力更強(qiáng),適合潮濕的地下車庫、游泳館等場所。與鋼制橋架相比,鋁合金橋架重量更輕,安裝便捷,且不易產(chǎn)生電化學(xué)腐蝕,尤其適合與銅纜搭配使用,避免不同金屬接觸產(chǎn)生的腐蝕反應(yīng)。

Aluminum alloy cable trays exhibit stability in humid environments. Aluminum alloy itself has a certain degree of corrosion resistance, and a layer of oxide film will naturally form on its surface. This oxide film can prevent water vapor and oxygen from further corroding the internal materials, and can maintain good condition in humid indoor and outdoor environments. The aluminum alloy bridge frame treated with anodizing has an increased thickness of surface oxide film and stronger corrosion resistance, making it suitable for damp underground parking lots, swimming pools and other places. Compared with steel cable trays, aluminum alloy cable trays are lighter in weight, easier to install, and less prone to electrochemical corrosion. They are especially suitable for use with copper cables to avoid corrosion reactions caused by contact between different metals.

塑料合金電纜橋架專為極端潮濕環(huán)境設(shè)計。它由多種高分子材料復(fù)合而成,具有的防水性和耐腐蝕性,不吸水、不導(dǎo)電,能完全隔絕水汽侵入。在長期浸泡于水或高濕度的環(huán)境中,如水利工程、地下隧道等,塑料合金橋架不會出現(xiàn)膨脹、開裂,能穩(wěn)定保護(hù)電纜。其表面光滑易清潔,即使沾染泥漿、污水,也能輕松擦拭干凈,減少污垢對橋架的侵蝕。不過,塑料合金橋架的承重能力相對較弱,更適合敷設(shè)輕型電纜,如通信電纜、控制電纜等。

Plastic alloy cable trays are designed specifically for extremely humid environments. It is composed of various polymer materials and has excellent waterproof and corrosion-resistant properties. It does not absorb water or conduct electricity, and can completely isolate water vapor from entering. In long-term immersion in water or high humidity environments, such as water conservancy projects, underground tunnels, etc., plastic alloy cable trays will not expand or crack, and can stably protect cables. Its surface is smooth and easy to clean, even if it is contaminated with mud or sewage, it can be easily wiped clean, reducing the erosion of dirt on the bridge. However, the load-bearing capacity of plastic alloy cable trays is relatively weak, making them more suitable for laying lightweight cables such as communication cables, control cables, etc.

本文由濟(jì)南電纜橋架友情奉獻(xiàn).更多有關(guān)的知識請點(diǎn)擊 http://m.h3022.cn 真誠的態(tài)度.為您提供為的服務(wù).更多有關(guān)的知識我們將會陸續(xù)向大家奉獻(xiàn).敬請期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://m.h3022.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.山東電纜橋架