山東電纜橋架安裝規范解析

電纜橋架的安裝需遵循嚴格規范,以保障其承載電纜的性和穩定性,同時為后續依據。安裝規范貫穿于準備、施工及驗收的全過程,每個環節都有明確要求。

The installation of cable trays must follow strict specifications to ensure the safety and stability of the cables they carry, and to serve as a basis for future reference. Installation standards run through the entire process of preparation, construction, and acceptance, with clear requirements for each link.

安裝前的準備工作是規范執行的基礎。需根據設計圖紙核對現場環境,確認橋架的敷設路徑、安裝位置及標高是否與圖紙一致,同時檢查路徑上是否存在障礙物,如管道、梁柱等,若有沖突需提前協調調整。其次,對進場的電纜橋架及附件(如支架、連接件、固定件等)進行外觀檢查,確保無變形、損壞、銹蝕等情況,材質和規格符合設計要求,必要時可核對產品相關合格證明文件。此外,準備好所需的安裝工具,如電鉆、扳手、水平儀等,確保工具完好且符合使用標準。

The preparation work before installation is the foundation for standardized execution. Firstly, it is necessary to verify the on-site environment according to the design drawings, confirm whether the laying path, installation position, and elevation of the bridge are consistent with the drawings, and check whether there are obstacles on the path, such as pipelines, beams, and columns. If there are conflicts, they need to be coordinated and adjusted in advance. Secondly, conduct a visual inspection of the incoming cable trays and accessories (such as brackets, connectors, fixings, etc.) to ensure that there is no deformation, damage, rust, etc., and that the materials and specifications meet the design requirements. If necessary, check the relevant product qualification certificates. In addition, prepare the necessary installation tools such as drills, wrenches, level gauges, etc., to ensure that the tools are in good condition and meet safety usage standards.

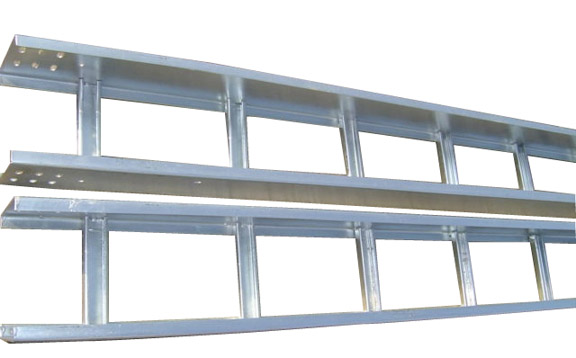

支架安裝是橋架固定的關鍵環節,需嚴格遵循規范。支架的間距應根據橋架規格、承載重量及安裝環境確定,通常在 1.5 米 3 米之間,間距過大可能導致橋架下垂變形。支架的固定方式需根據墻體、樓板等基層材質選擇,如在混凝土基層上可采用膨脹螺栓固定,在鋼結構上可采用焊接或螺栓連接,確保固定牢固可靠,避免松動。支架安裝時需保持水平或垂直,同一方向的支架應在同一直線上,偏差不超過規定范圍,以保證橋架安裝后的平整度。

The installation of brackets is a crucial step in fixing cable trays and must strictly comply with regulations. The spacing between brackets should be determined according to the specifications, load-bearing capacity, and installation environment of the bridge, usually between 1.5 meters and 3 meters. Excessive spacing may cause the bridge to sag and deform. The fixing method of the bracket needs to be selected according to the material of the base layer such as the wall and floor. For example, expansion bolts can be used to fix it on the concrete base layer, and welding or bolt connections can be used on the steel structure to ensure firm and reliable fixation and avoid loosening. When installing the bracket, it should be kept horizontal or vertical, and brackets in the same direction should be on the same straight line, with a deviation not exceeding the specified range, to ensure the flatness of the bridge after installation.

橋架的組裝與連接需符合規范要求。橋架之間的連接應采用專用連接件,連接時需緊密牢固,縫隙處可根據需要設置密封墊,防止灰塵、水汽進入。對于直線段橋架,其長度超過一定范圍(通常為 30 米)時,應設置伸縮節,以應對溫度變化引起的熱脹冷縮,避免橋架變形。在轉彎、分支處,需使用相應的彎通、三通等配件,確保橋架走向平滑過渡,轉彎半徑應滿足電纜彎曲半徑的要求,避免電纜因彎曲過度受損。

The assembly and connection of the bridge frame must comply with the specifications. The connection between cable trays should use specialized connectors, which should be tightly and firmly connected. Sealing gaskets can be installed at the gaps as needed to prevent dust and moisture from entering. For straight cable trays, when their length exceeds a certain range (usually 30 meters), expansion joints should be installed to cope with thermal expansion and contraction caused by temperature changes and avoid deformation of the tray. At bends and branches, corresponding fittings such as bends and tees should be used to ensure a smooth transition in the direction of the bridge. The turning radius should meet the requirements of the cable bending radius to avoid damage to the cable due to excessive bending.

橋架的敷設與固定也有明確規范。敷設時,橋架應與地面保持平行或垂直,排列整齊,層次分明,不同電壓、不同用途的電纜應分槽敷設,若需共槽敷設,需采取隔離措施。橋架與支架之間的固定應牢固,每個橋架少應有兩個固定點,防止橋架在受力時滑動。在穿越防火墻、樓板等部位時,需按規范要求進行防火封堵,使用防火材料填充縫隙,防止火災蔓延。

There are also clear specifications for the laying and fixing of cable trays. When laying, the cable tray should be kept parallel or perpendicular to the ground, arranged neatly and with clear layers. Cables of different voltages and purposes should be laid in separate slots. If they need to be laid in the same slot, isolation measures should be taken. The fixation between the bridge and the bracket should be firm, and each bridge should have at least two fixing points to prevent the bridge from sliding under stress. When passing through firewalls, floor slabs, and other areas, fireproof sealing should be carried out according to regulatory requirements, and fireproof materials should be used to fill gaps to prevent the spread of fire.

安裝后的檢查驗收是規范執行的收尾環節。檢查橋架的整體平整度,用水平儀檢測直線段是否水平,垂直度是否符合要求,偏差應控制在允許范圍內。其次檢查連接部位是否牢固,支架是否穩定,無松動、晃動現象。然后核對橋架的標高、位置及走向是否與設計一致,配件安裝是否齊全。,清理安裝過程中產生的雜物,確保橋架內部干凈整潔,為后續電纜敷設創造良好條件。

The inspection and acceptance after installation is the final stage of standardized execution. Firstly, check the overall flatness of the bridge frame, use a level to check whether the straight sections are horizontal and whether the verticality meets the requirements, and the deviation should be controlled within the allowable range. Next, check if the connection parts are secure, if the bracket is stable, and if there is no looseness or shaking. Then check whether the elevation, position, and direction of the bridge are consistent with the design, and whether the installation of accessories is complete. Finally, clean up any debris generated during the installation process to ensure that the interior of the cable tray is clean and tidy, creating favorable conditions for subsequent cable laying.

本文由山東電纜橋架友情奉獻.更多有關的知識請點擊 http://m.h3022.cn 真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://m.h3022.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.山東電纜橋架