電纜 “退燒” 有妙招:網格橋架散熱效率飆升 70% 的實戰攻略

當電纜在運行中因過載而 “發燒”,不僅威脅電力傳輸,更可能引發火災隱患。作為電纜的 “散熱盔甲”,網格橋架在應對這一問題時,若能通過科學優化,將散熱效率提升 70%,就能有效為電纜 “退燒”。從根源解決過載問題,到挖掘橋架散熱潛力,每個環節都藏著突破的關鍵。

When cables become overheated due to overload during operation, it not only threatens the safety of power transmission but may also pose a fire hazard. As the "heat dissipation armor" of cables, grid trays can effectively reduce cable overheating by increasing heat dissipation efficiency by 70% through scientific optimization when addressing this issue. From solving the overload problem at the root to tapping into the heat dissipation potential of the bridge, there are key breakthroughs hidden in every link.

一、追根溯源:找準電纜過載的 “病根”

1、 Tracing back to the source: Identifying the root cause of cable overload

電纜過載發熱,首要任務是排查根源。先檢查用電設備是否超出電纜額定承載功率,例如老舊線路接入過多大功率電器,或新設備安裝未匹配合適規格電纜。再查看電纜是否存在短路、接觸不良等故障,這些問題會導致局部電流異常增大,產生大量熱量。此外,電纜長期高負荷運行,絕緣層老化也會加劇發熱情況。只有精準定位過載原因,才能對癥下藥 —— 若是功率超標,需及時更換更大規格的電纜;若因故障導致,必須立即斷電檢修,修復后再恢復供電。

The primary task for cable overload heating is to investigate the root cause. First, check if the electrical equipment exceeds the rated carrying capacity of the cable, such as connecting too many high-power electrical appliances to old lines, or installing new equipment without matching suitable cable specifications. Re check if there are any faults such as short circuits or poor contacts in the cable, which can cause abnormal increase in local current and generate a large amount of heat. In addition, long-term high load operation of cables and aging of insulation layers can also exacerbate heating conditions. Only by accurately identifying the cause of overload can we prescribe the right medicine - if the power exceeds the standard, it is necessary to replace the cable with a larger specification in a timely manner; If it is caused by a malfunction, the power must be immediately cut off for maintenance, and the power supply must be restored after repair.

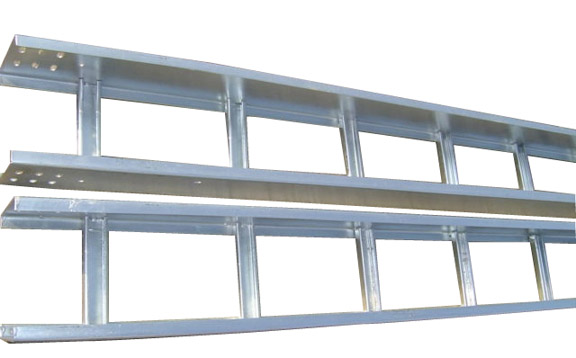

二、橋架改造:釋放網格橋架的 “散熱潛能”

2、 Bridge renovation: unleashing the "heat dissipation potential" of grid bridge structures

網格橋架的開放式結構本就具備天然散熱優勢,想要進一步提升效率,可從布局與設計著手。優化橋架安裝位置,將其設置在通風良好的區域,避免靠近熱源或封閉角落。同時調整橋架走向,減少不必要的彎曲與纏繞,確保空氣能在橋架內自由流通。對于多層橋架,層間需保持少 20 厘米的間距,防止下層電纜產生的熱量向上堆積。還可在橋架底部加裝導流板,引導冷空氣從底部進入,熱空氣從頂部排出,形成定向對流通道,加速熱量散發。通過這些改造,網格橋架的散熱效率將獲得顯著提升。

The open structure of grid bridge already has natural heat dissipation advantages. To further improve efficiency, we can start with layout and design. Firstly, optimize the installation position of the bridge and place it in a well ventilated area, avoiding proximity to heat sources or enclosed corners. At the same time, adjust the direction of the bridge to reduce unnecessary bending and entanglement, ensuring that air can freely circulate inside the bridge. For multi-layer cable trays, a minimum distance of 20 centimeters should be maintained between layers to prevent the heat generated by the lower cables from accumulating upwards. A guide plate can also be installed at the bottom of the bridge to guide cold air to enter from the bottom and hot air to be discharged from the top, forming a directional convection channel to accelerate heat dissipation. Through these modifications, the heat dissipation efficiency of the grid bridge will be significantly improved.

三、輔助散熱:為電纜 “降溫” 加把力

3、 Auxiliary heat dissipation: adding strength to the "cooling" of cables

除了橋架自身優化,搭配輔助散熱措施能事半功倍。在電纜表面涂刷散熱涂料,這種特殊涂料可增大電纜表面的散熱面積,加速熱量傳導。在橋架周圍安裝軸流風扇,強制空氣流動,帶走電纜散發的熱量。對于關鍵線路或發熱嚴重的區域,可采用熱管散熱技術,將電纜的熱量快速傳導遠處,降低局部溫度。此外,在電纜密集處填充相變材料,當溫度升高時,相變材料吸收熱量發生物態變化,從而穩定環境溫度,緩解電纜發熱問題。

In addition to optimizing the bridge structure itself, using auxiliary heat dissipation measures can achieve twice the result with half the effort. Brushing heat dissipation coating on the surface of the cable can increase the heat dissipation area of the cable surface and accelerate heat conduction. Install axial fans around the cable tray to force air flow and remove the heat emitted by the cables. For critical circuits or areas with severe heat generation, heat pipe heat dissipation technology can be used to quickly transfer the heat of cables to distant locations and reduce local temperatures. In addition, phase change materials are filled in densely populated areas of cables. When the temperature rises, the phase change materials absorb heat and undergo a change in state, thereby stabilizing the ambient temperature and alleviating the problem of cable heating.

四、智能監測:實時掌握電纜 “健康狀態”

4、 Intelligent monitoring: Real time monitoring of the "health status" of cables

引入智能監測系統,為電纜運行裝上 “千里眼”。在電纜關鍵節點安裝溫度傳感器,實時監測電纜表面溫度,一旦超過預設閾值,立即發出警報。利用紅外熱成像技術,定期掃描電纜與橋架,直觀呈現溫度分布,快速定位發熱點。將監測數據接入智能管理平臺,通過數據分析預測電纜過載風險,提前采取措施。例如,根據歷史溫度數據與用電負荷變化,動態調整用電分配,避免電纜長時間處于高負荷狀態。

Introduce an intelligent monitoring system and install a "thousand mile eye" for the safe operation of cables. Install temperature sensors at key nodes of the cable to monitor the surface temperature of the cable in real-time. Once the preset threshold is exceeded, an alarm will be immediately triggered. Using infrared thermal imaging technology, regularly scanning cables and cable trays to visually present temperature distribution and quickly locate hotspots. Connect monitoring data to the intelligent management platform, predict cable overload risks through data analysis, and take measures in advance. For example, based on historical temperature data and changes in electricity load, dynamically adjust electricity allocation to avoid cables being in a high load state for a long time.

本文由濟南電纜橋架友情奉獻.更多有關的知識請點擊 http://m.h3022.cn 真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://m.h3022.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.山東電纜橋架