電纜橋架鏈接件的多樣化連接方式解析

電纜橋架作為電力與信號傳輸系統的基礎設施,其鏈接件的連接方式直接影響系統的穩定性、性及維護便捷性。根據不同的工程需求與環境條件,電纜橋架鏈接件形成了多種成熟的連接方案,以下從技術特點與應用場景兩方面進行解析。

As the infrastructure of power and signal transmission systems, the connection method of cable trays directly affects the stability, safety, and maintenance convenience of the system. According to different engineering requirements and environmental conditions, cable tray connectors have formed various mature connection schemes. The following analysis is based on technical characteristics and application scenarios.

一、基礎連接方式的技術演進

1、 Technological evolution of basic connection methods

螺栓固定連接

Bolt fixed connection

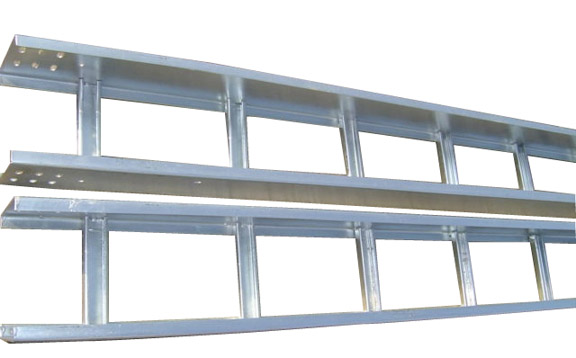

作為傳統的連接形態,螺栓固定通過鍍鋅螺栓與防松墊片組合,利用橋架側邊預留的孔位實現緊固。該方式對施工平整度要求較高,需確保螺栓均勻受力以避免橋架變形。規范要求連接處接觸電阻不超過0.1Ω,安裝后需用萬用表檢測電氣連續性。此類連接常見于直線段橋架拼接,尤其在需要承受重載的工業場景中表現穩定。

As the most traditional form of connection, bolt fixation is achieved through a combination of galvanized bolts and anti loosening washers, utilizing the reserved holes on the side of the bridge frame for fastening. This method requires a high level of construction flatness, ensuring that the bolts are evenly stressed to avoid deformation of the bridge. The specification requires that the contact resistance at the connection should not exceed 0.1 Ω, and a multimeter should be used to check the electrical continuity after installation. This type of connection is commonly used in the splicing of straight cable trays, especially in industrial scenarios where heavy loads need to be withstood, exhibiting stability.

卡扣式快速連接

Snap on quick connect

針對機房擴容等空間受限場景,卡扣式連接采用工程塑料與金屬復合材質,通過預制卡槽實現接插式組裝。其內部嵌裝的彈性導電片可維持電氣連通,但需注意環境溫度對塑料件的影響。當作業溫度超出-15℃60℃范圍時,建議改用全金屬連接器。此類連接方式顯著縮短了施工周期,特別適用于需不停電擴容的敏感區域。

For space limited scenarios such as computer room expansion, snap on connections are made of engineering plastic and metal composite materials, and plug-in assembly is achieved through prefabricated card slots. The elastic conductive sheet embedded inside can maintain electrical connectivity, but attention should be paid to the impact of environmental temperature on plastic parts. When the operating temperature exceeds the range of -15 ℃ to 60 ℃, it is recommended to use all metal connectors instead. This type of connection significantly shortens the construction period and is particularly suitable for sensitive areas that require uninterrupted power expansion.

二、特殊場景的適應性連接方案

2、 Adaptive Connection Scheme for Special Scenarios

鉸鏈式活接連接

Hinge type flexible joint connection

在設備轉角或檢修口區域,鉸鏈式活接通過旋轉軸實現橋架方向轉換。其內置的限位裝置可固定45°、90°等標準轉角,同時集成接地銅排保障等電位連接。安裝時需預留充足操作空間,并在轉角兩端增設固定支架以分散重力。該方案有效解決了復雜布線場景中的方向調整難題。

In the equipment corner or access area, hinged joints achieve bridge direction conversion through a rotating shaft. The built-in limit device can fix standard turning angles such as 45 ° and 90 °, while integrating grounding copper bars to ensure equipotential connection. Adequate operating space should be reserved during installation, and fixed brackets should be added at both ends of the corner to disperse gravity. This solution effectively solves the problem of direction adjustment in complex wiring scenarios.

伸縮節補償連接

Expansion joint compensation connection

針對溫度變化引發的熱脹冷縮問題,伸縮節由滑動套筒與緩沖墊組成。規范要求直線段橋架超過30米時必須設置此類裝置,金屬橋架伸縮量按0.2mm/℃·m計算。調試階段需進行全行程伸縮測試,并涂抹硅脂保持密封橡膠條彈性。該設計在大型公共建筑及跨區域橋架系統中應用廣泛。

In response to the thermal expansion and contraction caused by temperature changes, the expansion joint is composed of a sliding sleeve and a buffer pad. The specification requires that such devices must be installed when the straight section of the bridge exceeds 30 meters, and the expansion and contraction of the metal bridge shall be calculated at 0.2mm/℃· m. During the debugging phase, a full stroke expansion test is required, and silicone grease is applied to maintain the elasticity of the sealing rubber strip. This design is widely used in large public buildings and cross regional bridge systems.

三、創新連接技術的突破應用

3、 Breakthrough application of innovative connectivity technology

夾持式免工具連接

Clamping type tool free connection

通過特殊設計的夾持結構,該方式可快速固定不同尺寸的橋架段。其安裝效率較傳統螺栓連接提升40%,且無需工具即可完成拆卸。夾持力通過機械杠桿原理放大,確保連接強度滿足振動環境要求。該技術已應用于數據中心等需要維護的場景。

By using a specially designed clamping structure, this method can quickly fix bridge sections of different sizes. Its installation efficiency is 40% higher than traditional bolt connections, and it can be disassembled without the need for professional tools. The clamping force is amplified through the mechanical lever principle to ensure that the connection strength meets the requirements of the vibration environment. This technology has been applied to scenarios such as data centers that require efficient maintenance.

模塊化組合連接

Modular combination connection

現代工程常采用混合連接方案,如主干線路使用螺栓連接保證強度,分支線路采用卡扣連接便于調整。關鍵節點配置鉸鏈活接提升靈活性,形成“剛柔并濟”的連接體系。配套的連接件臺賬管理制度可記錄安裝時間與檢測數據,實現全生命周期追溯。

Modern engineering often adopts a hybrid connection scheme, such as using bolt connections to ensure strength for main lines and snap connections for branch lines for easy adjustment. The key nodes are equipped with hinge joints to enhance flexibility and form a connection system that combines rigidity and flexibility. The supporting connector ledger management system can record installation time and testing data, achieving full lifecycle traceability.

四、連接技術的選型原則

4、 Principles for Selecting Connection Technologies

環境適應性

Environmental adaptability

室外橋架需考慮防水密封,雨季前應檢查連接處密封性;腐蝕性環境應選用316不銹鋼連接件,并加裝防松螺紋膠。

Outdoor cable trays need to consider waterproof sealing, and the sealing of connections should be checked before the rainy season; 316 stainless steel connectors should be selected for corrosive environments, and anti loosening thread glue should be added.

電氣連續性

Electrical continuity

除鍍鋅橋架外,其他材質連接需跨接接地線,截面積不小于4mm?。伸縮節等可動部位應采用編織銅線連接,確保等電位要求。

Except for galvanized cable trays, connections made of other materials require a cross grounding wire with a cross-sectional area of not less than 4mm?. Flexible parts such as expansion joints should be connected with braided copper wires to ensure equipotential requirements.

維護便利性

Maintain convenience

高頻維護區域建議采用免工具連接件,卡扣式設計可縮短50%的檢修時間。關鍵連接點應預留檢測窗口,便于紅外測溫等預防性維護。

It is recommended to use tool free connectors in high-frequency maintenance areas, and the snap on design can shorten maintenance time by 50%. Key connection points should have reserved detection windows for preventive maintenance such as infrared temperature measurement.

電纜橋架鏈接件的連接方式已從單一螺栓固定發展為多技術融合的體系。通過科學選型與規范施工,可構建起既滿足力學要求又具備電氣性的橋架系統,為電力傳輸提供可靠支撐。隨著智能建造技術的發展,具備自感知功能的智能連接件將成為新的發展方向。

The connection method of cable tray connectors has evolved from single bolt fixation to a multi technology integrated system. Through scientific selection and standardized construction, a bridge system that meets both mechanical requirements and electrical safety can be constructed, providing reliable support for power transmission. With the development of intelligent construction technology, intelligent connectors with self sensing functions will become a new direction of development.

本文由山東電纜橋架友情奉獻.更多有關的知識請點擊 http://m.h3022.cn 真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://m.h3022.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.山東電纜橋架